Hot Stamping

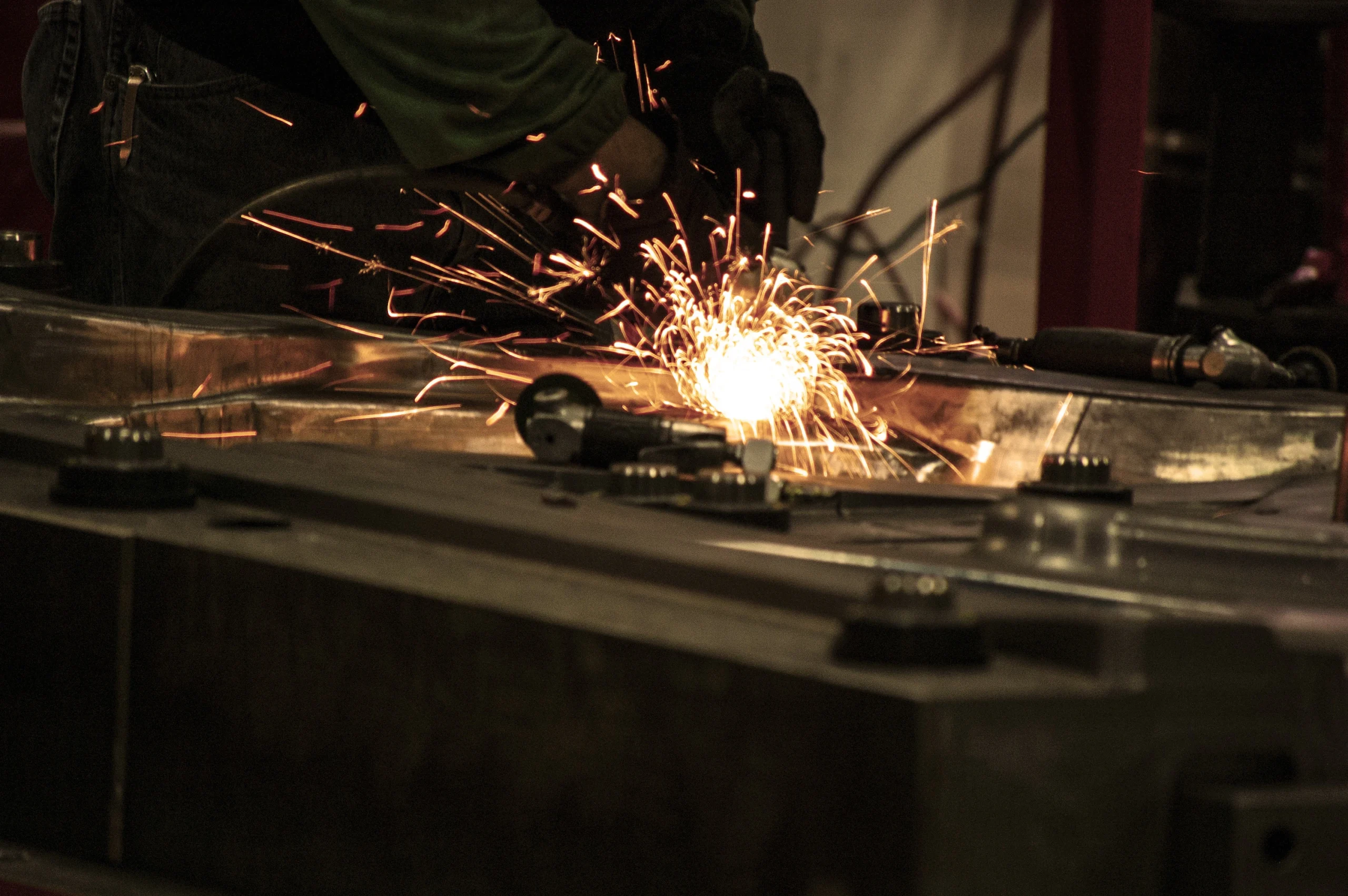

Telos Global operates one of the world’s largest hot stamping lines, enabling us to produce large hot stamp parts and accommodate multiple out dies. Our facility is designed for adaptability, allowing us to seamlessly integrate with a wide range of processes and support offloading from any supplier.

Professional Quality

Our equipment allows us to develop production-intent prototype tools, as well as design and manufacture new tools.

Eisenmann Roller Hearth Furnace

Width

Multiple Blanks: 2,650 mm

Single Blank (E.G. Door Ring): 2,700 mm usable width

Weight of Batch

For Smallest Batch, Length 500 mm max. 20 kg

For Batch Length of 1000 mm or longer max. 40 kg

Mass Throughput: max 7,600 kg/hr

Blanks

Material: 22MnB5 (Boron-Mangan-Steel)

Coating: Aluminum Al-Si or Uncoated

Length: 500-2,500 mm

Width: 2,700 mm max

Thickness: 0.5-4.0 mm

Furnace

Effective Heated Length: 40,000 mm

Overall Heated Length: 43,000 mm

Dew Point

Mesa Dew Point Monitoring and Regulatory System

Cosa laser Dew Point Monitoring System

Strothmann Automation

Gantry system at de-stack area to achieve 10 second cycle time, including date stamp & material thickness check

Date stamp and thickness check incorporated into one machine

Compact design to help reduce floor space

Press Load / Unload is a transferring rail system to achieve 10 second cycle time

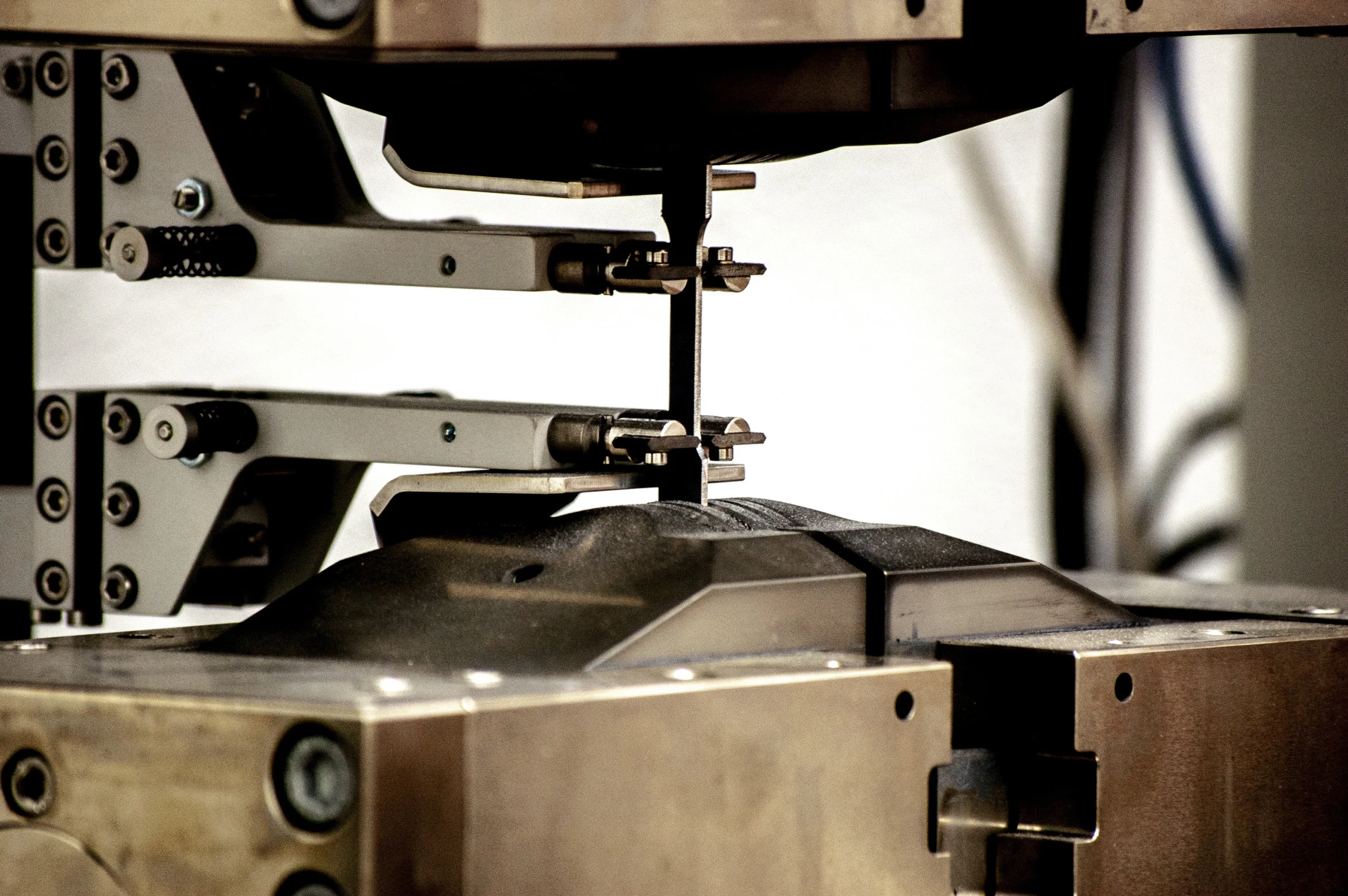

15,000 kn Hydraulic Press

Maximum Pressing Force: 15,000 kn

Maximum Net Retraction Force: 700 kn

Maximum Lifting Force at Return Speed: 200 kn

Slide Size: (L-R x F-B): 4000 x 3000 mm

Bolster Size: (L-R x F-B): 4000 x 3000 mm

Opening Between Housings (L-R ): 4050 mm

Opening Between Guide Bars (L-R): 3850 mm

Opening Between Housing (F-B): 3050 mm

Daylight: 2200 mm

Stroke of Slide: 1200 mm

Minimum Shut Height: 1000 mm

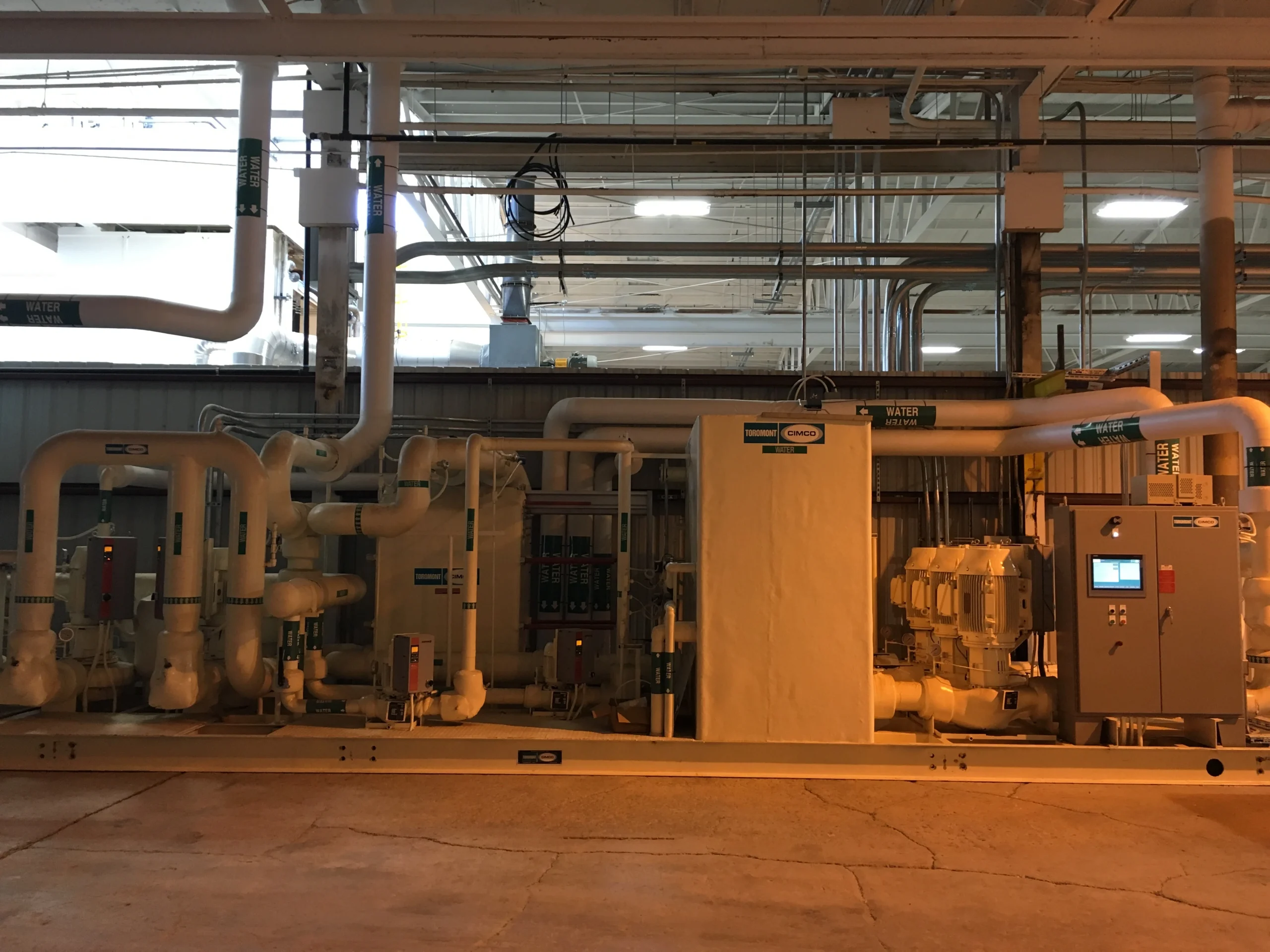

Cimco Water System

Highest Water Flow to the Dies:

Up to 600 gpm (2200 L/m) water flow per die half

Up to 95 psi pressure available

(3) 75 hp VFD pumps (one pump per die half, and one pump for standby)

Recipe and CIMCO programs that can control by flow or pressure

42 deg. F (6 deg. C) supply water temperature to the dies

Quality Lab

Telos Global has the latest technological equipment that is required for performing all the necessary tests for the hot stamping process.

Olympus Microscope

DSX Series of opto-digital microscopes

Zwick Hardness Tester

Calibration to BS EN ISO 6508-2 and ASTM E18-11 - Data output RS232 - Automatic test cycle with analogue sequence indication - 2 indenters: 1 x 120° diamond cone and 1 x 1/16" ball

LECO Puck Machine

Capable of both single and dual sample mounting

Zwick Tensile Machine

Z100 THW All-round Line Nominal force 100 kN - Test area (W x H) 640 x 1355 mm - High test speed (0.0001 ... 1500 mm/min) right up to nominal force

Ziess CMM with VDMIS 2018

6'x8' Bed with the ability to do full CMM layouts and capability studies.

Fraunhofer 3MA System

Non-Destructive Testing Equipment

Based on a calibration using destructively determined mechanical technological parameters (for example hardness, residual stress …) 3MA can measure these target values non- destructively.

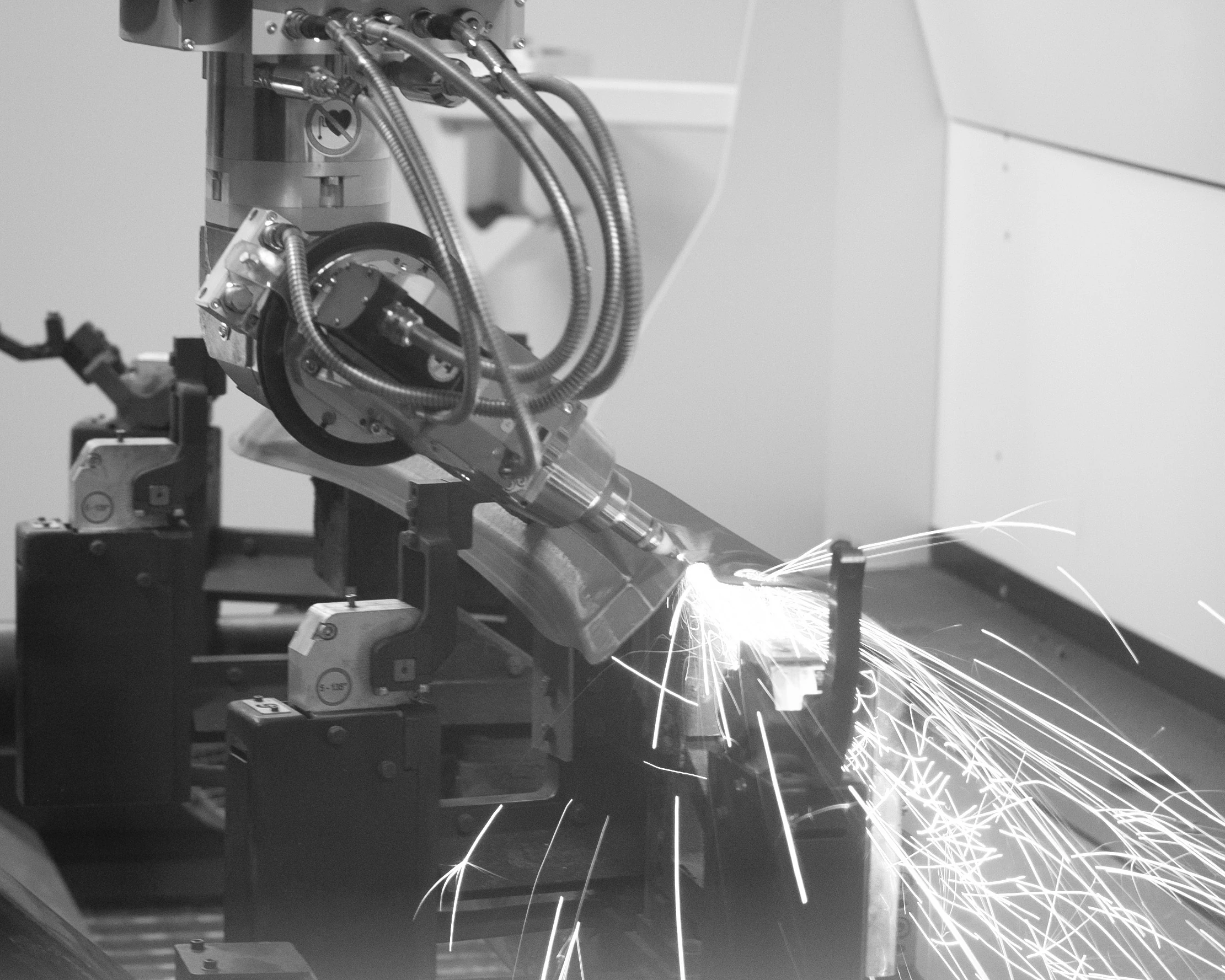

Tool and Die

IMTA Bridge Mill:

Bed Size X140" Y88.5" Z36"

24,000 RPM Spindle

24,000 Pound Bed Capacity